Survey and Scanning

mining servicesWithin CADDS Mining, we have a dedicated group of technical experts in the space of surveying and scanning. With decades of experience in the mining brownfields space, our team of highly qualified professionals can consult and collaborate with our clients and our internal teams to provide a full life-cycle service. We can connect surveying right through to engineering.

Our structure allows for our team to provide dedicated support to clients, rather than a constant stream of new faces, you can work with a direct team member throughout a project. Armed with the latest surveying instrumentation, we have the capability to capture, process, and present data using the industry’s most innovative methods. We deliver brownfields solutions designed around servicing a client’s distinct needs with superior accuracy.

Survey & scanning

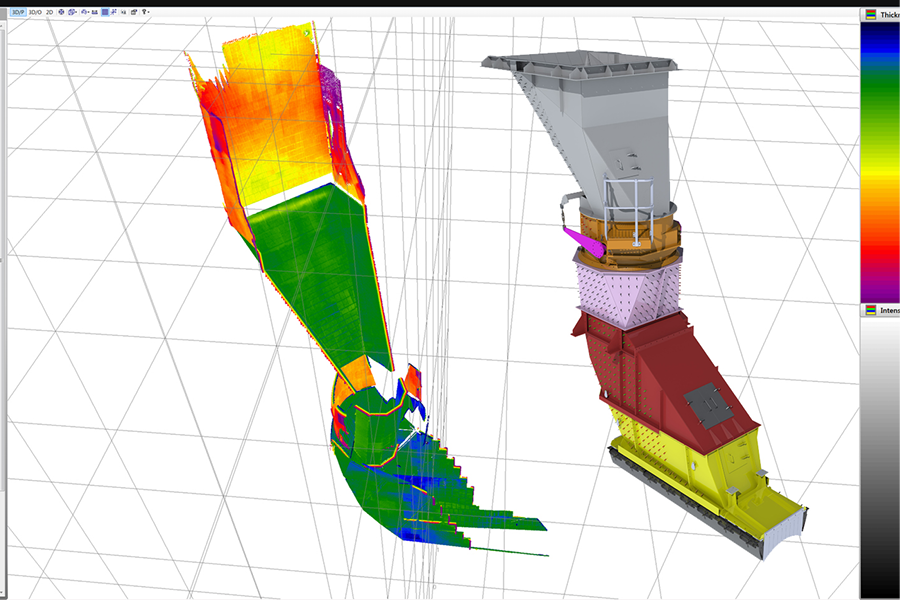

Internal scans and wear analysis

The use of laser scanners to conduct wear analysis for reports on plant, like chute liners is a common practice for our CADDS Mining team. Being a first-mover in this space, we have since developed tools and techniques to maximise our output and create ongoing cost efficiencies for our clients. Combining forces with our engineering team members, we are able to use high precision laser scanning technology and analysis software to record precise measurements of wearing materials in rapid time.

Customised reports for a client’s individual requirements can be drawn up, including data around the wear trend for lifeline and maintenance predictions. This insight is critical for reducing shut times and unnecessary costs.

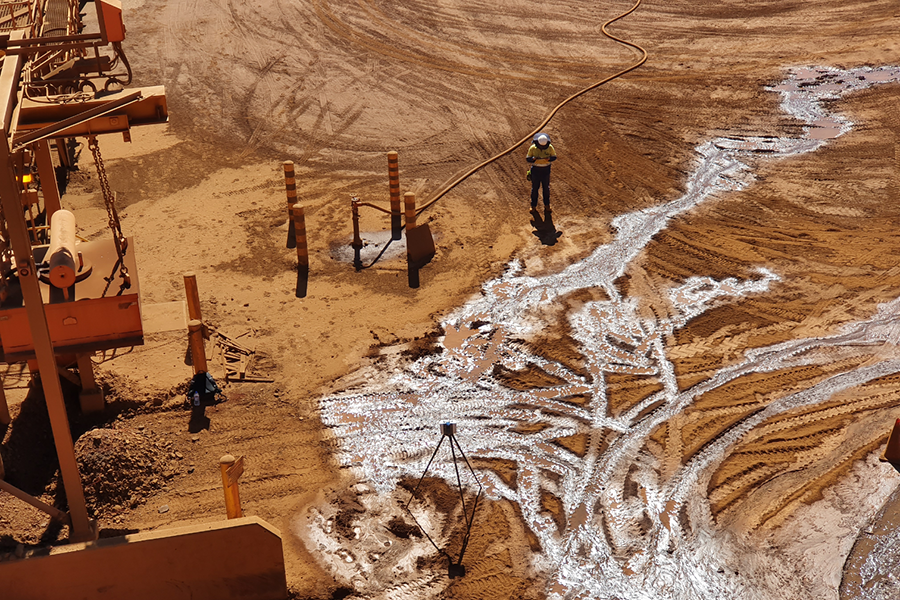

Drone work

Our team can provide aerial survey support through the use of drones. By erecting ground control points around a nominated area, and then flying a drone over the site, we can create ortho-rectified imagery and point cloud data for our clients.

Large scale scanning

Using GPS systems, 3D laser scanners, advanced robotic total stations, and digital level, we can observe, review, and establish levelled measurements to an exceptionally high degree of accuracy.

We complete a high precision control network install and scan target installation and coordinator, then use laser scanners to scan the whole plant site. From full workshops, and crushing buildings, to car dumpers, we can create a fully spatial, coordinated point cloud and orbital imagery of your plant.

Service location

Our state-of-the-art equipment is utilised to provide support services for the location and mapping of utility services across mining brownfield sites. With decades of experience, we have every confidence and capability to be able to accurately support our clients through feasibility studies, costings, and project planning.

Construction support

Our construction support can be as involved as our clients require. From assisting external construction teams, and our construction partners, install plant that has been designed and fabricated through CADDS Mining, to long-term secondments to assist in major projects. Our team is able to utilise our engineering data to set out on site, allowing contractors to complete projects.

As-building laser scanning

With powerful technology on hand, our team can assist in ensuring the accuracy of data and documentation of as-builts through scanning. As well as being engaged to help capture all relevant information required for projects to be undertaken. This efficient method provides an array of information that aids in supporting current and future projects.