Mining

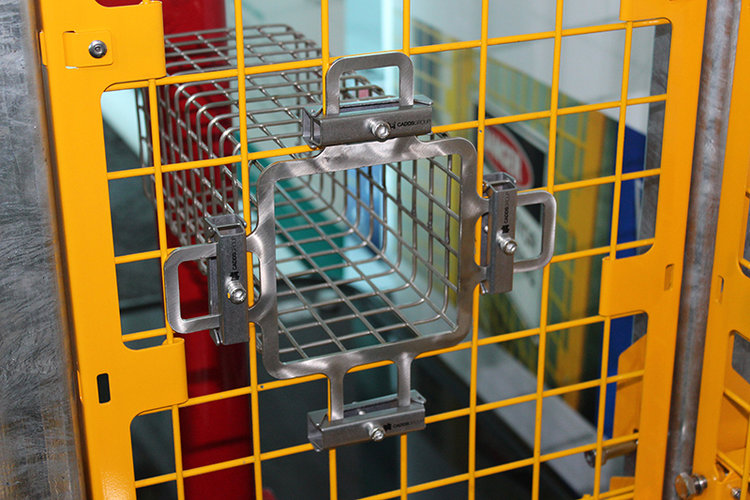

Guarding System Solution

Recent years have seen a strong industry focus on guarding compliance, CADDS Group, through CADDS Fabrication and CADDS Mining, has…

Case Study — Mining

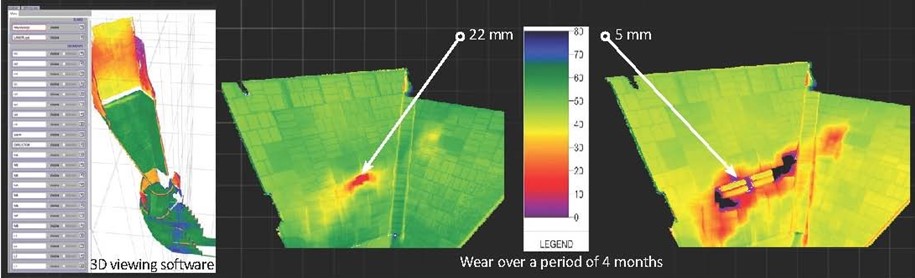

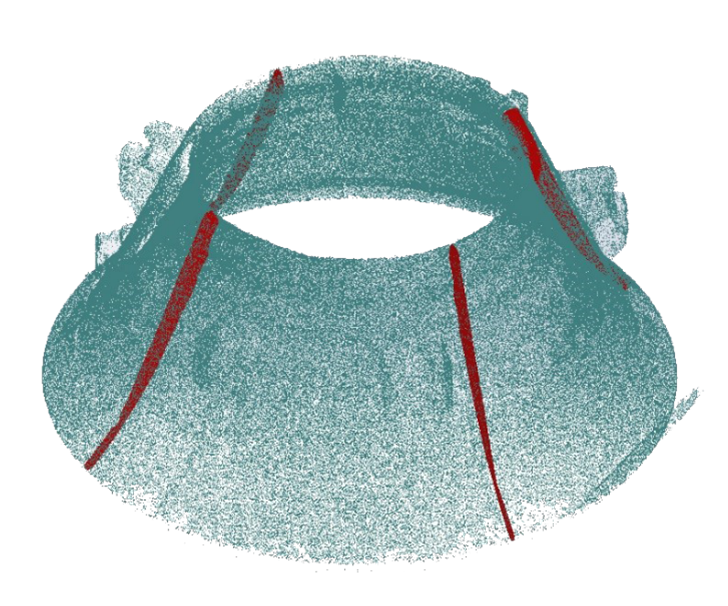

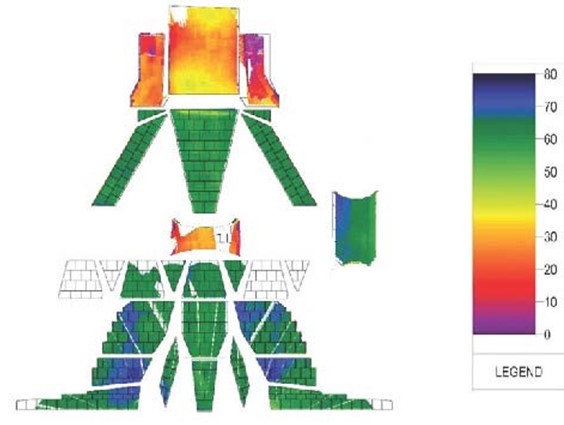

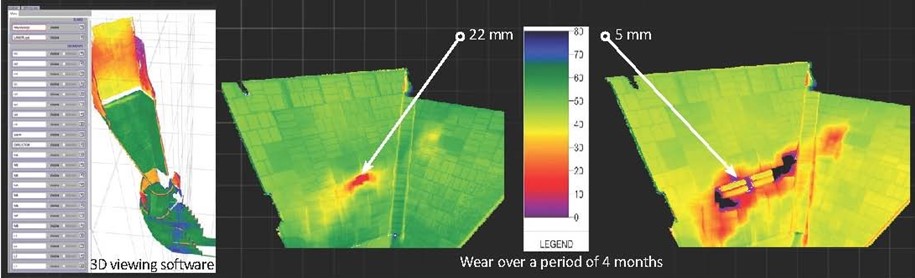

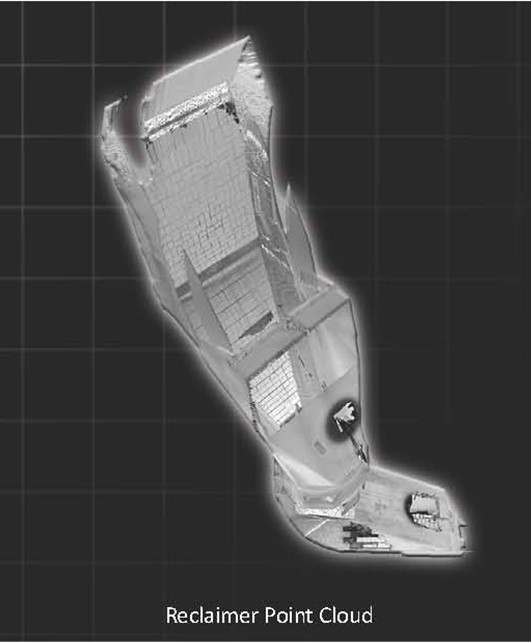

CADDS Group was one of the first vendors to offer the innovative use of laser scanners to conduct wear analysis reports, predominantly for chute liners initially.

We commenced wear analysis for Cape Lambert in 2015 and have since been running an ongoing dedicated wear team, with over 2,000 wear analysis projects completed in the last 5 years for assets of every kind.

CADDS have invested extensively into project-specific IT, workflows, development of custom scanning jig equipment, offshoring, process alignment and customised wear reports over the life of the project, in order to maximise cost efficiency, improve deliverable usability, and reduce report turnaround times to 10 days.

Over the course of the project, we have also introduced improvements to the deliverables to keep up with industry and technology changes, including 360° photos, visual asset management, and wear maps.

Project Features:

Project value completed to date

Mining

Recent years have seen a strong industry focus on guarding compliance, CADDS Group, through CADDS Fabrication and CADDS Mining, has…

Mining

Monitoring equipment within the mining sector is integral to the effective and efficient functioning of all operations and machinery on…

Mining

The team at CADDS Mining can provide car park design and documentation services, including traffic management plans and signage plans,…

Mining

The team at CADDS Mining are often engaged for both refurbishments or extensions to existing crib and WCs, as well…

Mining

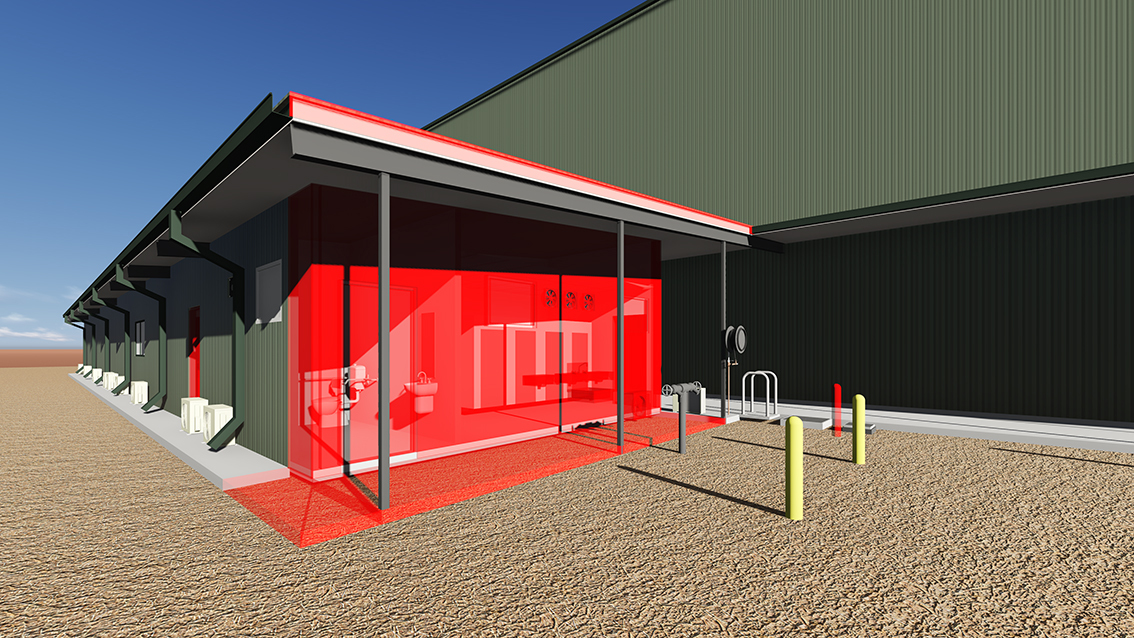

With the MEM (mobile equipment maintenance) workshop at Marandoo often at capacity, CADDS Mining was engaged to design a 2…

Mining

The client working at Western Turner approached our team with plans for a new tyre change facility at the mine…

Mining

Kerman Contracting approached our team at CADDS Mining with the brief of preparing the construction documentation for a large expansion…

Mining

CADDS Group won the contract directly with FMG for the design of a new accommodation village for FMG’s greenfield mine,…

Mining

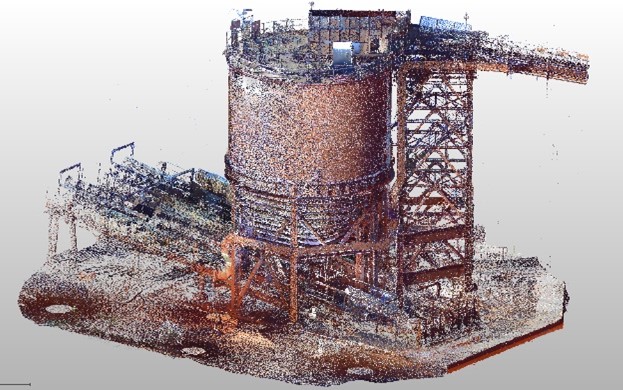

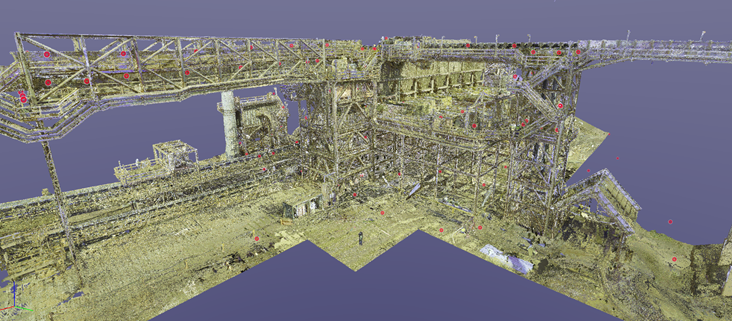

CADDS Group completed large-scale target installation, survey control network installation, 3D laser scanning and post-processing for the fixed plant at…

Sign up to stay connected, and stay in the know with all of CADDS Group.